新聞資訊

Address: Shenzhen City, Baoan District Xixiang Shu Donghua third industrial zone B building 7 floor

Telephone: 0755-2908-2001/2003

Fax: 0755-2908-2001

Q Q:540775041

Mailbox: 540775041@qq.com

URL: www.tj51.cn

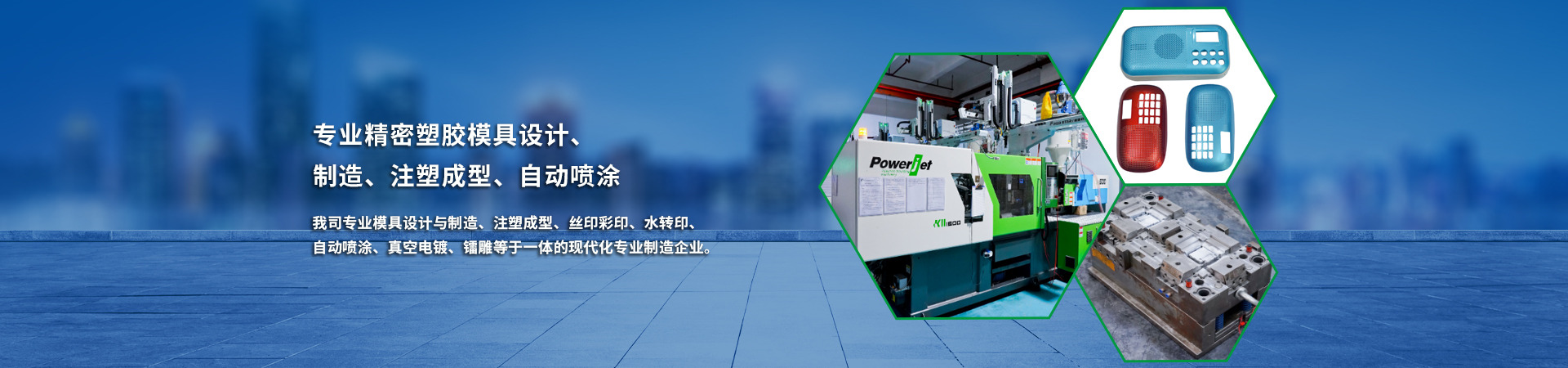

Shenzhen Tengfei plastic products Co., Ltd. - the most professional injection molding factory

| 發布時間:2017-09-09 |

Plastic molding is a general term for various processes that convert synthetic resins or plastics into plastic products. It is a large manufacturing sector in the plastics industry. Plastic processing generally includes plastic batching, molding, machining, bonding, modification and assembly. The latter four processes are carried out after the plastic has been molded into products or semi-finished products. It is also called plastic two times processing.

Injection molding plastic processing is developed with the development of synthetic resin, it and plastic machinery development promote each other. A lot of plastic forming technology is based on rubber, metal and ceramic processing. Plastic processing history can be traced back to 1890s, celluloid after birth, because of its flammable, use the method of moulding into blocks only, and then machined into sheets, sheet by hot molding. It was the earliest plastic process.

At present, the control system of the injection molding process is computer controlled, which can select the injection speed and the load of the clamping device. The process of operation, the movement of the side die to the movement into the mold, the working cycle of the ejector, and the control of the cylinder and die temperature. The method of setting and recording a particular mold and specific material in turn is of great value. Because there are a lot of variables in the process.

Common equipment options include: hydraulic fluid reservoir for the whole mold plastic feeder, quick die change system, rapid injection mold with sliding material cylinder, connected to the hydraulic system on the side of the core, manipulator type pickup system and air jet device (to remove the overflow generated in each cycle).

Because of the low viscosity of the polymer, it flows into the parting line to form a thin membrane. Therefore, thermosetting plastic products often need to be trimmed and removed. Molded burr removal is often the product of light or roll them by a device, in this device, knocking out the high speed plastic brittle edge layer.

The barrel temperature is controlled by hot water flowing through the jacket of the cladding barrel. Mold temperature control is most common with plug-in heaters, but can also be carried out by steam or by circulating hot oil. Highly controllable mold temperature is the most important to obtain homogeneous products.

755-2908-2001

755-2908-2001